RIGID PET FILM

Most films we taled is a flexible film. They are used in packing and printing. There is a flexible film, there is rigid film. Or called rigid sheet.Rigid PET Film is also a kind of pet film. The rigid pet film production method is coextruded film.It is also called APET film.

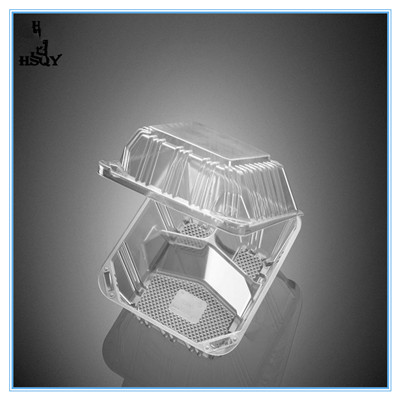

PET Rigid film has a high glossy and transparency,Good thermoforming and printing performance,which Can be widely used in including vacuum forming, food packaging, folding boxes, etc

Products Details:

- 1.Thickness 0.10-0.8mm(100-800microns)

- 2.Width Max:800mm

- 3.Hardness: Rigid

- 4.Color: clear/transparent and colored.

- 5.Core Tube: 3”

- 6.Package:by sheet or roll

Features :

- 1.Excellent transparency ,

- 2.chemical and oil Resistance ,

- 3.gas and water resistance ,

- 4.high impact resistance ,

- 5.non toxic and odorless .

Application:

- 1.For blister packing ,

- 2.Folding box,

- 3.Offset printing,

- 4.Vacuum forming,

- 5.Food tray packing,

- 6.Cup lids

- 7.Metallizing .

In them, the thermoforming box or bliseter box is the most applications.As rigid PET blister box,it has below freatures:

- The PET blister box has good mechanical properties. The impact strength is 3-5 times that of other films, and the folding resistance is good;

- PET blister box is resistant to oil, fat, dilute acid and alkali, and most solvents;

- The PET blister box has excellent high and low temperature resistance. It can be used for a long time in the temperature range of 120℃. Can withstand 150℃ high temperature and -70℃ low temperature in short-term use;

- The gas and water vapor permeability of the PET blister box is low. Has excellent barrier properties of gas, water, oil and peculiar smell;

- PET blister box has high transparency. It can block ultraviolet rays and has good gloss;

- The PET blister box is non-toxic, tasteless, and has good hygiene and safety performance. It can be directly used for food packaging.

The basic Production technology of Blister products

Production process flow chart of Blister products :

Sheet raw materials—blister forming— semi-finished product inspection— packaging and punching— finished product inspection — warehousing