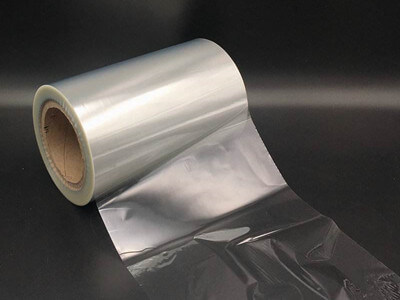

PET film and PVC film are the two common plastic films we use. Many times, we can’t judge how to use them well. This article will introduce the difference between PET film and PVC film from many aspects.

The difference between PET and PVC materials

What Is PET Material?

PET, also written as polyethylene terephthalate, is the most common thermoplastic resin in the polyester family. It consists of monoethylene glycol (MEG) and purified terephthalic acid (PTA) bound together to form a polymer chain. PET was originally used for synthetic fibers. Until now, most of its use (over 60%) is also in the production of synthetic fibers commonly known as nylon. Other uses include packaging and PET film. The density range of PET is 1.33 – 1.37 g/cm3.

What Is PVC Material?

PVC, also known as polyvinyl chloride, is the third most used synthetic plastic polymer in the world and one of the most widely used polymers in the world. It is polymerized from vinyl chloride monomer (VCM). The VCM then goes through a process called aggregation, resulting in the base PVC. Simply put, PVC is composed of 57% chlorine and 43% carbon. PVC comes in two general forms – rigid polymers and flexible plastics. The density of PVC ranges from 1.10-1.61 g/cm 3 .

Differences between PET and PVC properties.

PET Film Features:

- PET film has good air tightness, fragrance retention and moisture resistance.

- PET film has good transparency and gloss; moisture permeability decreases at low temperature.

- PET has good mechanical properties, and its tensile strength and impact strength are much higher than ordinary films.

- It is dimensionally stable and suitable for secondary processing such as printing and paper bags. It is an environmentally friendly shrink film.

- PET film also has excellent heat resistance, cold resistance and good chemical and oil resistance. But not resistant to strong alkali.

- PET film is also easy to recycle.

PVC Film Features:

- PVC films have excellent tensile strength and are resistant to chemicals and alkalis.

- PVC film has good toughness and strength. If you poke it with a finger or a pen, only a small hole will appear, and it will not crack like other films.

- PVC film has stable anti-corrosion, anti-ultraviolet erosion ability, and the surface has self-junction properties.

Both PET film and PVC film have good thermoforming properties, but PET film has higher thermal conductivity, so when making PET film, less energy is required and thermoforming time is faster.

The difference between PET and PVCUse

PET Film Application:

- PET film can be produced into mobile phone LCD protective film, LCD TV protective film, mobile phone buttons, etc. It is suitable for secondary processing such as printing and paper bags.

- PET film is mainly used in electrical, insulation, packaging, magnet containers, films, tapes, floppy disks, movies, video and entertainment software, etc.;

- Such as bronzing film, aluminized film, printing film, packaging film, packaging materials, composite materials, laser anti-counterfeiting composite film, drawing paper, electrical insulating materials and capacitors.

- PET film provides good ink adhesion, print quality and color reproduction, and has very good flattening properties.

- Because PET has strong barrier properties to water vapor, dilute acids, gases, oils and alcohols, it is often used in food and pharmaceutical packaging.

- It can also be used to make car exterior parts or microwave baking trays, outdoor billboards or models and many other fields.

PVC Film Application:

- PVC film can be made into swimming rings, toys, rain boots, tablecloths, decorative films, tapes, etc.

- It can be processed into packaging bags, tablecloths, curtains, etc. by cutting and heat sealing.

- It can be used in construction projects, such as the construction of greenhouses and plastic greenhouses, floor films, furniture decoration films.

- PVC film can also be used in advertising film, tablecloth, leather, etc.

PET or PVC, Which One Is Suitable For Packaging?

Both PET film and PVC film are suitable for packaging, but because of their different characteristics, the fields used for packaging are also different.

PET film is more suitable for the packaging of food and medicine, PET is a very strong and inert material, and it will not react with food. PVC is toxic and harmful to health, and is not suitable for the packaging of food and medicine.

PET film is more aesthetically pleasing for packaging, it absorbs colorants well and exhibits excellent adhesion in external printing. PVC does not have these characteristics.

PET film has higher durability, so it is more suitable for thermoforming packaging design than PVC film.

PVC film has advantages in hardness, so it is suitable for packaging that requires hardness. At the same time, the shrinkage of PVC film is very good, and it is also suitable for packaging that requires shrinkage.

PET vs PVCEnvironmental

An important advantage of PET film over PVC film is that it can be recycled, and PET is one of the most recycled plastics in the world. PET film regrind can be used to return PET sheet and can be made into a variety of different products. Therefore PET is very popular among many companies. For example, many supermarket chains now insist on packaging their products in PET instead of PVC.

PVC film contains heavy metals, and it releases hydrogen chloride when it burns. Compared with PET film, PVC recycled material is more difficult and expensive to use. And many international big names rarely use this material.

PET vs PVC Price

In terms of price, PET is about 20% cheaper than PVC. But PET has another advantage: its recyclable value is relatively high. Therefore, in the long run, the price of PET film will be cheaper than that of PVC film.

We are a PET film manufacturer and supplier in China, if you have any questions about PET film, please feel free to consult us. If you have a demand for PET film, welcome to inquire.