What is High Barrier Films?

High Barrier Films are a combination of co-extruded material. It has strong gas barrier properties and a polyolefin with strong thermal seam and moisture barrier properties. He was co-extruded. It is a multilayer structure film.

These high barrier films are a kind of Flexible packaging material. Normally, the thickness exceeds 25 microns. Thicker plastic materials are sheets. Its function is to prevent water, oxygen, light, and other elements from entering or leaving the product packaging.

Common High Barrier Materials Types

At present, the commonly used barrier materials in polymer materials mainly include the following:

1. Polyvinylidene chloride (PVDC)

PVDC has excellent barrier properties to oxygen and water vapor.

The high crystallinity, high density and the existence of hydrophobic group of PVDC make its oxygen permeability and water vapor permeability extremely low. Make PVDC have excellent gas barrier properties. Compared with other materials, it can better extend the shelf life of packaged items. Also, its printing adaptability is good. Easy to heat seal. So it is widely used in the field of food and medicine packaging.

2. Ethylene-vinyl alcohol copolymer (EVOH)

EVOH is a copolymer of ethylene and vinyl alcohol. Has very good barrier properties. This is because EVOH contains hydroxyl groups in its molecular chain. Hydrogen bonds are easily formed between the hydroxyl groups on the molecular chain. Strengthen the intermolecular forces. The molecular chains are packed more tightly. The crystallinity of EVOH is higher, so it has excellent barrier properties.

But, the EVOH structure contains a large number of hydrophilic hydroxyl groups. Make EVOH easy to absorb moisture. As a result, the barrier performance is reduced. Also, the large cohesive force and high crystallinity within and between molecules lead to poor heat sealing performance.

3. Polyamide (PA)

Generally speaking, nylon has good gas barrier properties. But the barrier to water vapor is poor. Strong water absorption. Swells with the increase of water absorption. Make the gas barrier and moisture barrier performance drop sharply. Its strength and packaging dimensional stability will also be affected.

Besides, nylon has excellent mechanical properties. Strong and wear-resistant. Good cold and heat resistance. Good chemical stability. Easy to process. Good printability. But the heat sealability is poor.

PA resin has certain barrier properties. But the high moisture absorption rate affects its barrier properties. So generally it cannot be used as an outer layer.

4. Polyester (PET, PEN)

The most common and widely used barrier material in polyester is PET. PET is symmetrical due to its chemical structure. The molecular chain has good planarity. The molecular chains are tightly packed. Easy to crystallize orientation. These characteristics make it have excellent barrier properties.

In recent years, PEN has also developed rapidly. It has good hydrolysis resistance. Chemical resistance and UV resistance. The structure of PEN is like PET. The difference is that the PET main chain contains a benzene ring. The main chain of PEN is a naphthalene ring.

Because the naphthalene ring has a greater conjugation effect than the benzene ring. The molecular chain is more rigid. The structure is flatter. So, PEN has better performance than PET.

| Barrier material | Advantage | Disadvantage |

| PVDC | gas-barrier, water-based, and chlorine-element | it is a banned material in some European countries |

| EVOH | gas barrier, good water | easy moisture absorption, poor heat sealability |

| PA | good gas barrier properties, excellent mechanical properties, | poor water barrier properties |

| PET, PEN | good gas barrier, good water resistance, and good weatherability | Cost is expensive |

High barrier material technology

To improve the barrier properties of barrier materials, the following technical methods are often used.

1. Multi-layer composite

Multi-layer composite refers to the composite of two or more films with different barrier properties through a certain process. In order for the permeating molecules to reach the inside of the package. They have to pass through several layers of membranes. Membranes equal extending the permeation path. As a result, the barrier performance is improved.

This method combines the advantages of various membranes. A composite film with excellent comprehensive performance is produced. The process is simple.

But compared with its high barrier materials, this method produces thicker films. Prone to problems such as bubbles or cracks and wrinkles that affect the barrier performance. Moreover, the equipment requirements are relatively complicated and the cost is relatively high.

2. Surface coating

Surface coating is the use of physical meteorological deposition (PVD), chemical vapor deposition (CVD), atomic layer deposition (ALD), molecular layer deposition (MLD), layer-by-layer self-assembly (LBL). Thus, a dense coating with excellent barrier properties is formed on the surface of the film.

However, these methods are time-consuming, expensive in equipment, and complicated in processes. Moreover, the coating may produce defects. Such as pinholes and cracks during the production process.

3. Nanocomposites

Nanocomposite materials are nanocomposite materials prepared by the intercalation composite method, in-situ polymerization method. Or sol-gel method by using non-permeable and large aspect ratio sheet-like nanoparticles. The addition of flaky nanoparticles can not only reduce the volume fraction of the polymer matrix in the system. But also reduce the solubility of penetrating molecules. It can also extend the penetration path of penetrating molecules. Reduce the diffusion rate of penetrating molecules. Improve the barrier performance.

4. Surface modification

Since the surface of the polymer is often in contact with the external environment. It is easy to affect the surface adsorption, barrier properties, and printing of the polymer.

In order to make the polymer better used in daily life, the surface of the polymer is usually treated. Mainly include surface chemical treatment, surface graft modification, and plasma surface treatment.

This type of method is easy to meet the technical requirements. The equipment is simpler. The one-time investment cost is low, but it cannot achieve long-term stability. Once the surface is damaged, the barrier performance will be seriously affected.

5. Biaxially oriented technic

By biaxial stretching, the polymer film can be oriented in both vertical and horizontal directions. So that the order of molecular chain arrangement is improved. The packing is more compact. It makes it more difficult for small molecules to pass.

Thereby improving the barrier performance. This method is complicated. Because it makes The preparation process of high-barrier polymer films with levitation. And the barrier performance is difficult to be significantly improved.

Application of high barrier materials

In fact, high barrier films have already appeared in daily life. Current high-molecular barrier materials are used in food and pharmaceutical packaging, electronic device packaging, solar cell packaging, and OLED packaging.

1. Food and medicine packaging

EVOH seven-layer co-extruded high barrier film

Food and pharmaceutical packaging is currently the most used field of high-barrier materials. The main purpose is to prevent oxygen and water vapor from entering the packaging to spoil food and medicines. It reduces its shelf life.

For food and pharmaceutical packaging, barrier requirements are generally not particularly high. The water vapor transmission rate (WVTR), oxygen transmission rate (OTR) of materials requires a barrier that should be lower than 10g/m2/day and 100cm3/m2/day.

2. Electronic device packaging

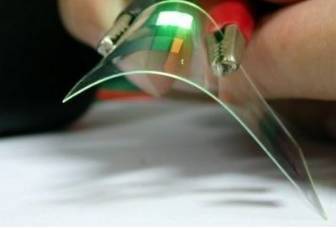

Electronic device packaging film

With the rapid development of modern electronic information, people have put forward higher requirements for electronic components.

Toward portability and multi-function development. This puts forward higher requirements for electronic device packaging materials. It must have good insulation. It must also be able to protect it from external oxygen and water vapor corrosion. And it must have a certain strength. This requires the use of polymer barrier materials.

Generally, the barrier properties of packaging materials for electronic devices need water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) to be lower than 10-1g/m2/day and 1cm3/m2/day.

3. Solar cell packaging

Solar cell packaging film

Since solar energy is exposed to the air all year-round, oxygen and water vapor in the air can easily corrode the metallization layer outside the solar cell. It seriously affects the use of solar cells.

So, it is necessary to use high-barrier materials for the encapsulation of solar cell modules. This not only ensures the service life of the solar cell. It also enhances the battery’s anti-strike strength.

The barrier properties of solar cells for packaging materials are that the water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) should be lower than 10-2g/m2/day and 10-1cm3/m2/day

4. OLED packaging

OLED packaging film

OLED has been entrusted with the important task of next-generation displays from the early stage of development. But, the short life span has always been a major problem that restricts its commercial application.

The main reason that affects the service life of OLEDs is that electrode materials and luminescent materials are very sensitive to oxygen, water, and impurities.

It is easy to be contaminated which leads to the degradation of device performance. Thereby reducing the luminous efficiency and shortening the service life.

To ensure the luminous efficiency of the product and prolong its service life, the device must be insulated from oxygen and water during packaging.And to ensure that the service life of the flexible OLED display is greater than 10,000 hours. The water vapor transmission rate (WVTR) and oxygen transmission rate (OTR) of the barrier material must be lower than 10-6g/m2/day and 10-5cm3/m2/day.

Its standards are far higher than the barrier performance requirements in the fields of organic photovoltaics, solar cell packaging, and food, medicine, and electronic device packaging technology.

So, a flexible substrate material with excellent barrier properties must be selected to package the device. To meet the strict requirements of product life.

| Application | Water vapor transmission rate | Oxygen transmission rate |

| Food and medicine packaging | < 10g/m2 / day | < 100cm3 /m2 / day |

| Electronic device packaging | < 10-1g/m2 / day | < 1cm3 /m2 / day |

| Solar cell encapsulation | < 10-2g/m2 / day | < 10-1cm3 /m2 / day |

| OLED package | < 10g-6/m2 / day | < 10-5cm3 /m2 / day |

Contact

Dehui Film is a high barrier film supplier in China.If you have any need on barrier films,kindly contact us or email us. info@dhfilmtech.com