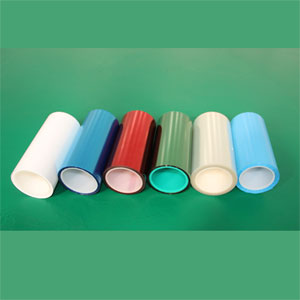

Chemical Treated PET Film,Chemical Coated Polyester Film for printing,metallizing

Description

Chemical Treated PET Film or Chemical Coated Polyester Film is one kind of BOPET film which is unsaturated resins formed by the reaction of dibasic organic acids and polyhydric alcohols.

To improve the surface properties of the PET film, to improve the adaptability of printing and the bonding force of the vacuum aluminized layer. Corona treatment is usually used to increase the surface tension of the film. However, the corona method has problems such as timeliness. Especially in a high temperature and high humidity environment. The film tension after corona treatment is easily attenuated.But, the chemical coating method does not have such a problem. Therefore, it is favored by the printing industry and the aluminum plating industry.

In China,the Chemical Treated PET Film manufacturer companies have developed a series of PET chemical coating products.

- 1) Coating with water-soluble polymers can increase the surface tension of the PET film.

- 2) Coating with acrylic emulsions can improve printing adaptability (water-soluble polymers can be used) Ink).

- 3) Coated with aqueous polyurethane solution. It can strengthen the bonding force between the aluminized layer and the PET base film. And can increase the thickness of aluminized layer.

- In addition, the coating method can also be used to produce high-barrier films and antistatic films.

The chemical coated sides can be 1 side or 2 sides. It is chemically pre-treated on one side to give improved ink/metal adhesion.The chemically treated PET film can be used in various printing and lamination applications.

Features

- Smooth texture

- High adhesion

- Good wettability

- Abrasion & heat resistance

- Fine finish

Specifications

| Item | Test methods | Units | Typical value | |

| Thickness | GB/T6672 | μm | 12 | |

| Tensile strength | MD | ASTM D882 | Mpa | 200 |

| Tensile strength | TD | ASTM D882 | % | 200 |

| Elongation at break | MD | ASTM D882 | % | 100 |

| Elongation at break | TD | ASTM D882 | 100 | |

| Heat shrinkage | MD | 150℃ 30min | % | 1.8 |

| Heat shrinkage | TD | 150℃ 30min | % | 0.5 |

| Surface wetting tension | treated | ASTM D2578 | – | 48 |

| Surface wetting tension | untreated | ASTM D2578 | – | 43 |

| Haze | ASTM D1003 | % | 3 | |

| Gloss | ASTM D2457 | % | 128 | |

| Total luminous transmission | ASTM D1003 | % | 90 |

Typical Applications

- (1) Used for metallized the PET film;

- (2) To meet customized specifications for lamination and printing;

- (3) Used for flexible packaging

- (4) Used for advertisement and printing