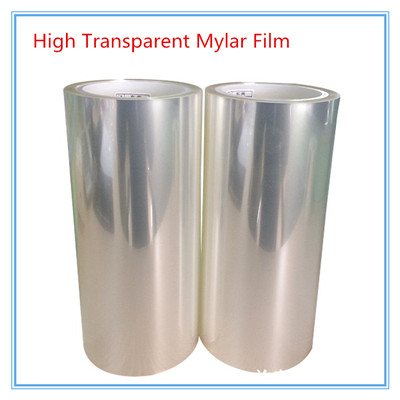

Mylar sheet for sale

- Thickness: 50 mic – 350 mic

- MOQ:1 Ton

Description

Mylar sheet (MYLAR sheet) PET polyester film is a film made of dimethyl terephthalate and ethylene glycol. It is heated with the help of related catalysts. Through transesterification and vacuum polycondensation, and biaxially stretched.

To make Mylar, super-heated polyethylene terephthalate (PET) film is put on a roll and stretched. One side is smooth, but the other is not so that it can be applied more easily as a coating to various products.

Molten polyethylene terephthalate (PET) is extruded as a thin film onto a chilled surface.

The film is drawn biaxially. Special machinery may be used to draw the film in both directions at once.

Properties

- Dimensionally stable

- Straight and excellent tear strength,

- Heat-resistant and cold-resistant,

- Moisture and water resistance,

- Chemical resistant,

- Super insulation performance,

- Excellent electrical, mechanical, heat, and chemical resistance properties.

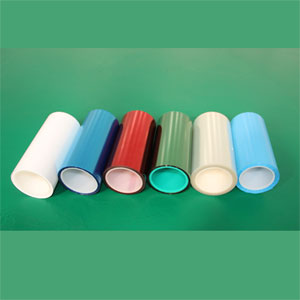

Mylar Sheet Types

- 1-Mylar Sheet color: milky white, black, natural color, transparent color, and many other color classifications.

- 2-Mylar Sheet materials: PET Mylar flakes, PVC Mylar flakes, PC Mylar flakes, fireproof Mylar flakes, etc.

Applications

It can be used as an insulating material for motors, capacitors, coils, and cables. It can also be made into composite insulating material with barley paper.

It has been widely used in the electrical insulation industry. It is suitable for gaskets, and protection of electronics, household appliances, displays, motor slots, and peripheral equipment.

PS: Can replace general tape. Suitable for packaging electronic components when they are packaged on the machine. This can make the electronic components safer in use.